When it comes to keeping your machines running smoothly, one of the most critical components to pay attention to is the V-belt. Often overlooked until it fails, the V-belt is responsible for transferring power between pulleys, helping your machines perform at their best. But with so many types, materials, and sizes available, how do you choose the perfect V-belt for your specific needs?

In this guide, I’ll explain everything you need to know to make an informed decision. Whether you’re replacing an old V-belt or selecting one for a new machine, this post will cover essential factors to ensure your V-belt fits perfectly and performs efficiently.

What is a V-Belt and How Does It Work?

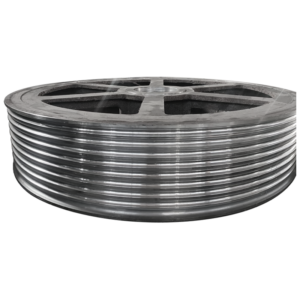

A V-belt is a looped belt with a V-shaped cross-section that is used in a wide variety of mechanical power transmission applications. It works by fitting into a corresponding groove on pulleys, where the friction between the belt and the pulleys allows power to be transmitted smoothly.

This simple design helps V-belts maintain consistent speed and torque, making them an ideal choice for many industrial machines, vehicles, and HVAC systems. The shape of the V-belt provides excellent grip, preventing slippage, and allowing it to handle heavy loads efficiently.

The Different Types of V-Belts: Which One is Right for Your Machine?

Not all V-belts are created equal. Depending on the nature of your machine and the type of load it bears, you may need a specific type of V-belt. Some common types include:

• Classic V-Belt: The traditional V-belt, widely used in general applications.

• Cogged V-Belt: Designed with notches to improve flexibility and reduce friction, ideal for higher-speed applications.

• Wedge V-Belt: Offers higher power transmission capacity due to its increased width, used in heavy-duty industrial machines.

• Polyurethane V-Belt: Known for its durability and resistance to wear and environmental factors, often used in harsh conditions.

Each type serves a different purpose, so understanding your machine’s specific requirements is key to making the right choice.

How to Measure a V-Belt for Accurate Fit and Performance

A V-belt that doesn’t fit correctly can cause slippage, premature wear, or even failure, which could lead to costly repairs. Measuring your V-belt for the correct size is essential for maintaining machine efficiency. Here’s how to do it:

• Length: Measure the total length of the belt, which can typically be found on the belt itself or in the manufacturer’s specifications.

• Width: Measure the width at the widest point of the belt’s V-section.

• Pitch: The distance between the grooves on the belt. This ensures it will properly fit into the pulley grooves.

Accurate measurements will help you find a V-belt that fits perfectly, ensuring optimal performance and extending the life of both the belt and your machine.

The Importance of V-Belt Material Selection for Durability

V-belts are made from various materials, each suited to different operational conditions. The most common materials include:

• Rubber: Flexible, cost-effective, and widely used in many applications. However, it may degrade faster under high temperatures.

• Polyurethane: Offers better durability and resistance to oil, heat, and chemicals, making it ideal for harsh environments.

• Neoprene and EPDM: Known for their ability to withstand high temperatures, ozone, and weathering, these materials are commonly used in automotive and heavy-duty applications.

Choosing the right material ensures the V-belt can handle the stresses of your machine’s operation and last longer under demanding conditions.

Common Signs Your V-Belt Needs Replacing

Knowing when to replace a V-belt is critical for avoiding machine downtime and costly repairs. Some common signs that a V-belt may need replacement include:

• Cracking or Fraying: This is a sign of wear that can lead to eventual failure.

• Slipping or Squealing: If the V-belt is slipping or making noise, it could be too loose or worn out.

• Decreased Performance: A worn-out V-belt may reduce the efficiency of your machine, causing it to work harder and consume more energy.

If you notice any of these signs, it’s time to inspect and potentially replace your V-belt.

V-Belt Tensioning: How to Achieve Proper Tension for Maximum Efficiency

Proper tensioning is essential for maximizing the lifespan and efficiency of your V-belt. If a V-belt is too tight, it can cause excessive wear on the pulleys and the belt itself. On the other hand, if it’s too loose, it can slip, leading to power loss and increased wear.

To achieve the right tension, refer to the manufacturer’s guidelines for your specific machine. Most V-belts will require periodic adjustment to maintain optimal tension, so regular maintenance is key to preventing unnecessary wear and ensuring your machine continues to run smoothly.

How Temperature and Environment Affect V-Belt Performance

V-belts can be affected by environmental factors such as temperature, humidity, and exposure to chemicals. For example, high temperatures can cause rubber belts to harden and crack, while cold temperatures may make the material brittle. Likewise, exposure to oils, solvents, or UV light can degrade the belt over time.

To ensure your V-belt performs at its best, choose one that’s suited to your specific environmental conditions. For extreme temperatures or harsh chemicals, consider a polyurethane or neoprene V-belt for added durability.

The Role of V-Belts in Power Transmission: Why They’re Critical for Your Machines

V-belts play a crucial role in transferring power from the engine or motor to other parts of the machine. They provide a reliable connection between pulleys, allowing energy to be transmitted efficiently, which is especially important in systems that require precise speed control.

Without a properly functioning V-belt, machines would experience power loss, reduced efficiency, and potential damage to other components. Understanding this fundamental role can help you appreciate the importance of selecting the right V-belt for your machine.

How to Extend the Life of Your V-Belt: Tips for Maintenance and Care

Proper maintenance is the key to ensuring your V-belt lasts longer and performs efficiently. Here are a few tips to keep your V-belt in top condition:

• Regular Inspections: Check for wear, cracks, or signs of damage.

• Keep Pulleys Clean: Dirt and debris can cause additional wear on the belt and pulleys.

• Maintain Proper Tension: As mentioned, ensure the V-belt is properly tensioned to avoid unnecessary strain.

• Lubricate the Pulleys: This helps reduce friction and keeps the system running smoothly.

Taking the time to maintain your V-belt will pay off by extending its lifespan and preventing costly downtime.

Choosing the Right V-Belt for Heavy-Duty Applications

When it comes to heavy-duty machinery, not just any V-belt will do. These machines often require belts that can handle high loads and extreme conditions. For such applications, wedge V-belts or multi-ribbed belts are often the best choice as they offer higher power transmission capacity and better durability.

Make sure to choose a V-belt specifically designed for heavy-duty use, and always consult the machine manufacturer’s specifications to ensure compatibility.

Conclusion

Choosing the right V-belt is essential for maintaining your machine’s efficiency, reliability, and longevity. By understanding the different types of V-belts, how to measure them, and the factors that affect their performance, you can ensure your equipment operates at its best. Whether you’re dealing with temperature extremes, heavy-duty applications, or routine wear and tear, the right V-belt can make all the difference.

Regular maintenance, proper tensioning, and timely replacements will help you get the most out of your V-belts and keep your machines running smoothly for years to come.