1. Introduction

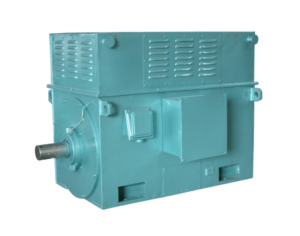

Low-speed, high-power electric motors are widely used in heavy-duty industrial applications where large torque at low rotational speeds is required. These motors are typically rated from hundreds of kilowatts to several megawatts, with rotational speeds below 1,000 RPM. Due to their robust structure and high efficiency, they play a critical role in high-demand systems such as mining, marine propulsion, cement production, and power plants.

2. Key Features and Benefits

- High torque output at low speeds

- Energy-efficient operation under continuous or heavy-load conditions

- Stable performance, even in harsh environments

- Long service life and low maintenance needs

3. Typical Application Scenarios

3.1 Mining Industry

In mining operations, particularly in crushing systems, conveyor belts, and hoists, low-speed, high-power motors are essential. These applications demand high torque to handle heavy materials such as ore, coal, and rock. Direct-drive configurations reduce the need for gearboxes, improving reliability and reducing maintenance.

3.2 Cement and Steel Plants

Rotary kilns, mills (such as ball mills or SAG mills), and other heavy rotating machinery in cement and steel industries require slow but powerful rotational force. These motors help maintain stable operation under varying loads and temperatures.

3.3 Marine Propulsion

Marine vessels such as ships and submarines use low-speed electric motors for propulsion systems. They provide the required thrust efficiently and reliably, often using synchronous motor configurations for precise speed control.

3.4 Hydropower Stations

In hydroelectric plants, large vertical or horizontal shaft motors drive turbines to generate electricity. The motors used must operate reliably at relatively low speeds, matching the slow rotation of turbine blades.

3.5 Wind Tunnels and Fans

Large industrial fans and wind tunnel systems require low-speed, high-power motors to move significant volumes of air under controlled conditions. These motors must provide consistent torque and smooth operation over long periods.

3.6 Paper and Pulp Industry

Paper mills involve large rollers and processing machines where high power at low speed is necessary for smooth and continuous production. Low-speed motors are preferred due to their reliability and ability to handle varying loads.

4. Technical Challenges and Considerations

- Cooling Requirements: Due to high power output and continuous duty, effective cooling methods (e.g., IC611, IC81W) are necessary to prevent overheating.

- Motor Size and Weight: These motors tend to be large and heavy, which requires specialized installation and foundation design.

- Starting Methods: Soft starters or variable frequency drives (VFDs) are often used to control inrush currents and provide smoother startup.

- Custom Design: Many applications require tailored solutions, including shaft dimensions, mounting types (e.g., B3, B35), and special insulation.

5. Market Trends

- Increasing demand for energy efficiency and reliability is driving the adoption of custom-engineered electric motors in industrial projects.

- The global push for electrification in industries such as marine and mining is further boosting demand for high-performance electric motors.

- Integration with digital control systems and IoT monitoring is becoming more common, especially in predictive maintenance applications.

6. Conclusion

Low-speed, high-power electric motors are indispensable in many industrial sectors where stable, continuous, and powerful motion is required. As industries evolve toward automation, energy saving, and low maintenance, the demand for these motors is expected to grow steadily. Manufacturers and suppliers must focus on customized design, advanced materials, and intelligent control systems to meet the increasingly complex needs of the market.