In modern mechanical power transmission, pulleys, taper bushes, and couplings are three essential components. Each of them plays a unique role under different working conditions, ensuring reliable performance and efficient power transfer.

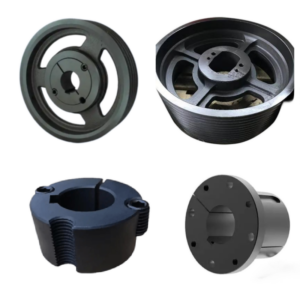

1. Pulleys

Pulleys transmit power through the friction between the belt and the pulley groove.

- Structure: Usually made of cast iron or steel, designed with standardized grooves and a lightweight structure.

- Advantages: Belt drives offer vibration damping, smooth operation, and lower alignment requirements. They are ideal for medium to low-speed applications with larger center distances.

- Applications: Commonly used in fans, pumps, compressors, and other industrial equipment.

2. Taper Bushes

Taper bushes are standardized locking devices, widely used with pulleys, sprockets, and other transmission parts.

- Working Principle: The tapered design provides a self-locking effect, ensuring a secure fit between the shaft and the mounted component.

- Advantages: Easy installation and removal, accurate positioning, and adaptability to different shaft tolerances.

- Applications: Frequently applied in pulley, sprocket, and gear assemblies.

3. Couplings

Couplings connect two shafts to transmit torque while compensating for misalignment.

- Types: Rigid couplings, flexible couplings, gear couplings, and disc couplings are among the most common.

- Functions: Besides transmitting torque, couplings help absorb shock and vibration, thereby protecting the machinery.

- Applications: Widely used in motor-to-reducer connections, pumps, and various industrial drive systems.

Conclusion

Pulleys enable flexible frictional transmission, taper bushes provide secure shaft connections, and couplings ensure efficient torque transfer and system protection. Together, they form the foundation of reliable mechanical power transmission. With the advancement of manufacturing technologies, these components continue to evolve, offering higher precision, durability, and performance to meet the growing demands of modern industry.