In modern mechanical transmission systems, belt pulley transmission remains an indispensable method of power transfer across numerous industrial sectors as a classic yet efficient approach. This seemingly simple mechanical device serves as a bridge for power transmission between electric motors and working machines with its unique advantages.

Basic Principles and Structural Components

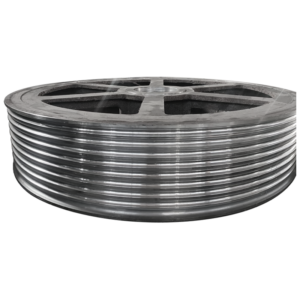

The belt pulley transmission system primarily consists of three basic components: the driving pulley, the driven pulley, and the transmission belt. The driving pulley is typically mounted on the output shaft of a power source (such as an electric motor), while the driven pulley connects to the driven equipment. When the motor starts, the driving pulley rotates, causing the driven pulley to turn synchronously through friction between the belt and pulley grooves, thereby achieving power transmission.

As the key component of the system, transmission belt materials have evolved from natural rubber to synthetic materials. Modern V-belts commonly use composite structures of high-strength synthetic rubber and fiber reinforcement layers, which not only improve transmission efficiency but also significantly extend service life. Pulleys are usually made of cast iron, cast steel, or aluminum alloy, with groove angles and dimensions precisely matched to the belt specifications to ensure optimal contact area and friction.

Technical Advantages and Application Fields

The continued importance of belt pulley transmission in modern industry stems from its multiple technical advantages. First, compared to gear transmission, belt drives offer excellent cushioning and vibration damping capabilities, effectively absorbing vibrations and shocks from power sources to protect driven equipment. Second, when the system is overloaded, belt slippage occurs, creating a “fail-safe” mechanism that prevents more severe mechanical damage.

In terms of spatial arrangement, belt drives demonstrate remarkable flexibility. The center distance between two shafts can be relatively large (typically up to 10 meters) without requiring strict parallelism, allowing for some angular misalignment. This characteristic makes them particularly suitable for industrial applications with space constraints. Additionally, belt drives operate with low noise, simple maintenance, and high cost-effectiveness, making them ideal for small to medium power transmission systems.

From an application perspective, belt pulley transmission is ubiquitous across industries. In manufacturing, it drives various machine tools, conveying equipment, and production lines; agricultural machinery such as harvesters and threshers rely on it for power transmission; auxiliary systems in automotive engines (like water pumps and generators) frequently use belt drives; and even household appliances like washing machines and vacuum cleaners incorporate this technology.

Design Considerations and Maintenance Essentials

Designing an efficient belt pulley transmission system requires consideration of multiple factors. The selection of transmission ratio directly affects output speed and torque, typically achieved by adjusting the diameter ratio of driving and driven pulleys. Belt speed is generally controlled between 5-25 m/s—excessive speed intensifies centrifugal effects, while insufficient speed reduces transmission efficiency. Determining the center distance must balance spatial constraints and belt lifespan, usually 1-1.5 times the sum of the two pulley diameters.

Routine maintenance is crucial for extending the service life of belt pulley systems. Regular inspection of belt tension is fundamental—excessive looseness causes slippage, while over-tightening increases bearing load. Technicians commonly use thumb pressure methods or specialized tension gauges for inspection. Belt wear, cracks, or hardening indicate replacement needs. Meanwhile, keeping pulley grooves clean to prevent oil contamination and maintaining pulley alignment (typically within 0.1 mm/m) are essential maintenance practices.

Technological Development and Future Trends

With advancements in materials science and manufacturing technology, belt pulley transmission systems continue to innovate. The application of high-performance polyurethane and aramid fibers has increased belt strength by over 30%. The emergence of synchronous belts (timing belts) addressed the slippage issues of traditional belt drives, finding applications in scenarios requiring precise synchronization, such as CNC machine tools.

The introduction of intelligent monitoring technology has brought new possibilities to belt transmission systems. Vibration sensors and temperature monitoring devices enable real-time system status assessment and maintenance cycle prediction. Some advanced manufacturers have begun implementing IoT technology for belt transmission system health management.

Despite competition from new transmission methods like direct drive technology, belt pulley transmission maintains its position in industrial power transmission due to irreplaceable advantages. Future development may focus on further improving efficiency (currently up to 98%), extending service life (high-quality belts can last 3-5 years), and enhancing environmental adaptability.

From the steam era to the electrification age, and now to the smart manufacturing era, belt pulley transmission—this seemingly simple mechanical device—continues to reinvent itself. It is not only a witness to industrial revolution history but also an indispensable “power link” in modern manufacturing. On the path toward efficient, reliable, and economical transmission solutions, belt pulley transmission technology will continue to evolve, providing silent yet resilient support for industrial production.