1. Introduction

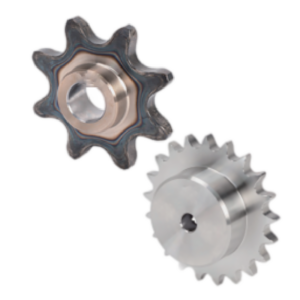

Chain sprockets are key components in power transmission systems and must be correctly matched with the corresponding roller chains to ensure smooth operation, durability, and efficiency.

Understanding sprocket standards and naming conventions is essential for engineers, purchasers, and international traders to avoid mismatches and costly errors.

This article provides an overview of common chain sprocket standards and explains the standard naming rules used in international practice.

2. Chain Sprocket Standards

Chain sprockets are manufactured according to the same standards as roller chains. The most widely used standards include:

- ANSI (American National Standards Institute)

Commonly used in North America. Typical chain sizes include #40, #50, #60. - ISO (International Organization for Standardization)

Widely used worldwide, especially in Europe and Asia. Typical chain sizes include 08B, 10B, 12B. - DIN (German Standard)

Closely aligned with ISO standards and commonly used in Europe. - JIS (Japanese Industrial Standards)

Used mainly in Japan and Japanese equipment. - GB / GB/T (Chinese National Standards)

Used in mainland China, largely compatible with ISO standards.

⚠️ Important: Different standards are not interchangeable. For example, an ANSI #50 sprocket cannot be used with an ISO 10B chain.

3. Chain Sprocket Naming Structure

A standard chain sprocket designation generally consists of the following elements:

Chain Type + Number of Strands + Number of Teeth + Sprocket Type + Bore Details (optional)

4. Chain Type Identification

4.1 ANSI Standard (American)

ANSI chain numbers are based on pitch in eighths of an inch.

| Chain Size | Pitch |

|---|---|

| #40 | 1/2 inch |

| #50 | 5/8 inch |

| #60 | 3/4 inch |

Example:

ANSI #50-20T sprocket

→ A sprocket for ANSI #50 chain with 20 teeth.

4.2 ISO / DIN Standard (European)

ISO chain numbers are based on pitch in sixteenths of an inch.

| Chain Size | Pitch |

|---|---|

| 08B | 1/2 inch |

| 10B | 5/8 inch |

| 12B | 3/4 inch |

Example:

ISO 10B-1-25T sprocket

→ ISO 10B single-strand sprocket with 25 teeth.

5. Number of Strands

Sprockets can be designed for single or multiple strand chains.

| Designation | Description |

|---|---|

| -1 | Single strand |

| -2 | Double strand |

| -3 | Triple strand |

Example:

08B-2-30T sprocket

→ Double-strand sprocket with 30 teeth.

6. Sprocket Types (Hub Design)

According to hub configuration, sprockets are typically classified as:

- Type A – Plate sprocket without hub

- Type B – Single hub sprocket

- Type C – Double hub sprocket

- Taper Lock Sprocket – Sprocket with taper bush

- QD Bushed Sprocket – Quick detachable bush design

Example:

ISO 10B-1-20T Type B sprocket

7. Bore and Mounting Details

Bore and mounting information is often specified separately, especially for finished bore sprockets.

Common terms include:

- Bore – Shaft hole diameter

- Pilot Bore – Pre-machined bore

- Finished Bore – Fully machined bore

- Keyway – Slot for parallel key

- Set Screw – Fixing screw for shaft locking

Example:

Bore 30 mm with keyway and set screws

8. Materials and Heat Treatment

Typical materials and surface treatments include:

- Carbon Steel (C45 / 1045)

- Alloy Steel

- Stainless Steel

- Induction Hardened Teeth

- Black Oxide / Zinc Plated Finish

Material selection depends on load, speed, and operating environment.

9. Complete Naming Examples

Example 1 (ISO Standard):

ISO 08B-1, 25T, Type B sprocket, bore 30 mm with keyway

Example 2 (ANSI Standard):

ANSI #50-2, 40T, Taper Lock sprocket

Example 3 (Engineering Drawing):

DIN 8187 – 10B – 1 – Z=20 – Type C

Material: C45

Bore: 35 mm, Keyway: 10 mm

10. Conclusion

Correct identification of chain sprocket standards and naming conventions is critical in mechanical design and international procurement.

Clear and standardized naming helps ensure compatibility, reduces errors, and improves communication between suppliers, engineers, and buyers.

By following the conventions outlined in this article, sprockets can be accurately specified for any industrial application.