Chains used in mechanical equipment come in a wide variety, with different materials and models suited for various working conditions and load requirements. Below is an analysis of common chain materials, models, and their comparisons.

I. Common Chain Materials and Characteristics

- Carbon Steel Chains

- Material: Low-carbon steel (e.g., Q235), medium-carbon steel (e.g., 45# steel), high-carbon steel.

- Features:

- Low cost, moderate strength, easy to process.

- Surface treatments like zinc plating, nickel plating, or blackening improve corrosion resistance.

- High-carbon steel chains offer greater hardness but lower toughness, suitable for high-load, low-impact applications.

- Applications: General machinery, conveyor systems, agricultural equipment.

- Alloy Steel Chains

- Material: 40Cr, 20Mn2A (with added chromium, manganese, etc.).

- Features:

- High strength, excellent wear resistance, and better fatigue resistance than carbon steel.

- Heat treatment (quenching, carburizing) further enhances performance.

- Applications: Mining machinery, heavy-duty conveyors, construction equipment.

- Stainless Steel Chains

- Material: 304, 316 stainless steel.

- Features:

- Strong corrosion resistance, ideal for humid or acidic/alkaline environments.

- Lower strength than alloy steel, higher cost.

- Applications: Food processing, chemical industry, marine equipment.

- Engineering Plastic Chains

- Material: Nylon (PA), polypropylene (PP), polyoxymethylene (POM).

- Features:

- Lightweight, corrosion-resistant, requires no lubrication, but has lower temperature and load resistance.

- Applications: Lightweight conveyors, packaging equipment, cleanroom environments.

II. Common Chain Models and Comparisons

1. Drive Roller Chains (ISO Standard)

| Model | Pitch (mm) | Tensile Strength (kN) | Characteristics | Applications |

|---|---|---|---|---|

| 08A | 12.7 | 13.8 | Light load, cost-effective | Small machinery, office equipment |

| 10A | 15.875 | 21.8 | Balanced performance, general use | Agricultural machines, conveyors |

| 12A | 19.05 | 31.1 | Medium-to-high load capacity | Industrial drives, motorcycles |

| 16A | 25.4 | 55.6 | Heavy-duty, high durability | Mining machinery, heavy equipment |

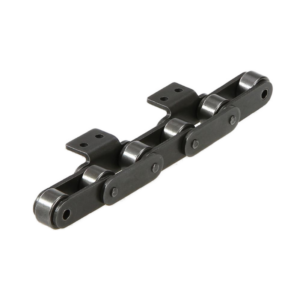

2. Conveyor Chains

| Model | Type | Characteristics | Applications |

|---|---|---|---|

| Leaf Chains | Extended pins, bent links | Impact-resistant, for heavy-load conveying | Construction, mining conveyors |

| Double-Speed Chains | Roller-equipped | Multiplies conveying speed, smooth operation | Assembly lines, automation |

| Top Plate Chains | Flat-top attachments | Ideal for material carrying | Food, packaging lines |

3. Special Chains

| Model | Characteristics | Applications |

|---|---|---|

| Silent Chains | Tooth engagement, ultra-low noise | Precision machinery, automotive timing systems |

| Drag Chains | Scraper attachments, wear-resistant | Wastewater treatment, coal conveyors |

| Anti-Corrosion Chains | Stainless steel or special coatings | Humid, corrosive environments |

III. Key Comparison Factors

- Load Capacity:

- Alloy steel > Carbon steel > Stainless steel > Engineering plastic.

- Corrosion Resistance:

- Stainless steel > Engineering plastic > Zinc-plated carbon steel > Plain carbon steel.

- Cost:

- Stainless steel > Alloy steel > Carbon steel > Engineering plastic.

- Suitable Environment:

- High temperature/heavy load: Alloy steel chains.

- Corrosive conditions: Stainless steel or plastic chains.

- Light load/low noise: Engineering plastic or silent chains.

IV. Selection Recommendations

- Heavy-Duty & High-Speed: Choose alloy steel roller chains (e.g., 16A, 20A).

- Corrosive Environments: Prioritize 316 stainless steel chains.

- Cleanroom Requirements: Engineering plastic or stainless steel top plate chains.

- Budget-Friendly Option: Zinc-plated carbon steel chains (e.g., 10A, 12A).

Select the material and model based on specific working conditions (load, speed, environment) and budget. For specialized needs, consult professional suppliers for custom solutions.