Pulleys are fundamental components in countless mechanical systems, from the serpentine belt drive in your car to complex conveyor systems in industrial plants. While their design might seem simple, the choice of material for a pulley is a critical decision that directly impacts performance, efficiency, durability, and cost. Selecting the wrong material can lead to premature wear, excessive noise, vibration, and even system failure.

This guide explores the most common pulley materials, their properties, advantages, disadvantages, and typical applications to help you make an informed choice.

Key Factors in Material Selection

Before diving into specific materials, consider these crucial factors:

- Application Load: Is the pulley subjected to light, medium, or heavy loads? High-tension systems demand high-strength materials.

- Operating Environment: Will the pulley be exposed to moisture, chemicals, extreme temperatures, or abrasive dust? Corrosion resistance is key here.

- Friction and Grip: The material’s coefficient of friction affects grip on the belt. Too little friction can cause slippage; too much can increase wear.

- Weight: Rotational inertia matters. Lighter pulleys allow for faster acceleration and deceleration, which is crucial in high-speed or servo applications.

- Cost: Budget constraints often play a decisive role, balancing initial material cost against the total cost of ownership, including maintenance and replacement.

- Noise and Vibration: Some materials, like plastics, naturally dampen noise and vibration better than metals.

Common Pulley Materials and Their Characteristics

1. Steel (Carbon Steel & Stainless Steel)

- Properties: High strength, excellent durability, and good wear resistance. Stainless steel (e.g., 304 or 316 grade) offers superb corrosion resistance.

- Advantages:

- Unmatched strength for high-load and high-torque applications.

- Resists deformation under heavy stress.

- Precise machining capabilities for critical tolerances.

- Stainless steel is ideal for harsh, corrosive environments (food processing, marine, chemicals).

- Disadvantages:

- Heavy, contributing to higher rotational inertia.

- Prone to rust (unless stainless, which is more expensive).

- Can be noisy and generate more vibration.

- Generally more expensive than other options like cast iron or plastic.

- Typical Applications: Heavy machinery, automotive engines, high-horsepower industrial drives, washdown environments.

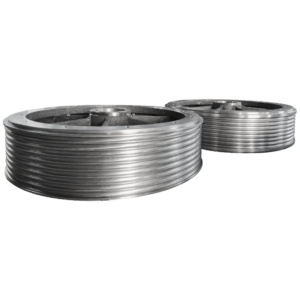

2. Cast Iron

- Properties: Excellent wear resistance, high compressive strength, and good vibration damping.

- Advantages:

- Superior durability and long service life under abrasive conditions.

- The graphite in its structure acts as a lubricant, reducing wear on the belt.

- Damps vibration effectively, leading to smoother operation.

- Relatively low cost for its durability.

- Disadvantages:

- Very heavy.

- Brittle and can fracture under impact or shock loading.

- Prone to corrosion (rust) if not properly coated or maintained.

- Typical Applications: Agricultural machinery, industrial conveyor systems, large drilling rigs, and applications where vibration damping is valued.

3. Aluminum

- Properties: Lightweight, good corrosion resistance, moderate strength, and excellent thermal conductivity.

- Advantages:

- Significantly lighter than steel, reducing rotational mass for improved efficiency and responsiveness.

- Naturally corrosion-resistant without needing coatings.

- Easy to machine, allowing for complex designs.

- Dissipates heat well, preventing overheating in high-speed applications.

- Disadvantages:

- Lower strength than steel, not suitable for very high-load applications.

- Softer material, making it more susceptible to wear and gouging.

- Generally more expensive than cast iron.

- Typical Applications: Aerospace systems, robotics, high-speed drives, packaging machinery, and any application where weight reduction is a priority.

4. Plastics (Polyamide/Nylon, Acetal/POM, Polyurethane)

- Properties: Lightweight, corrosion-proof, excellent noise damping, and self-lubricating.

- Advantages:

- Extremely lightweight and quiet operation.

- Immune to rust and resistant to many chemicals.

- Low coefficient of friction reduces belt wear.

- Cost-effective for high-volume production (e.g., injection molding).

- Disadvantages:

- Limited strength and load-bearing capacity compared to metals.

- Susceptible to creep (deformation under constant load) over time.

- Performance can be highly sensitive to temperature; may become brittle in cold or soften in heat.

- Typical Applications: Office machinery (printers, scanners), light-duty conveyors, textile machinery, food handling equipment, and consumer appliances.

5. Composites (Reinforced Polymers)

- Properties: Combines polymer resins (like epoxy) with reinforcing fibers (fiberglass, carbon fiber). Offers a unique strength-to-weight ratio.

- Advantages:

- Exceptionally strong yet very lightweight—often stronger than aluminum at a fraction of the weight.

- Excellent fatigue resistance and corrosion immunity.

- Can be engineered for specific properties like stiffness or friction.

- Disadvantages:

- Highest cost among common pulley materials.

- Manufacturing processes can be complex.

- Typical Applications: High-performance automotive accessories, advanced aerospace systems, and specialized industrial equipment where minimizing weight without sacrificing strength is critical.

Conclusion

There is no single “best” material for all pulleys. The optimal choice is a careful balance of engineering requirements and economic factors.

- Choose steel or cast iron for brute strength and durability in heavy-industry applications.

- Choose aluminum for a perfect blend of strength, lightness, and corrosion resistance in high-speed and general industrial uses.

- Choose plastic or composites for light-duty, corrosive, or noise-sensitive environments where weight is a primary concern.

By thoroughly evaluating the demands of your specific application against the properties of these materials, you can select the ideal pulley to ensure a reliable, efficient, and long-lasting drive system.