When it comes to precision, efficiency, and durability in machinery, timing pulleys play a critical role. Whether you’re designing a new system or upgrading an existing one, choosing the right timing pulley is essential to achieving optimal performance. But with so many options available, how do you make the best choice for your needs?

In this comprehensive guide, I’ll walk you through everything you need to know about timing pulleys. You’ll learn what they are, how they work, and the different types available for various applications. I’ll help you understand the importance of material selection and highlight key factors to consider, such as size, pitch, and tooth profile, to ensure you pick the perfect match for your setup.

I’ll also cover how to measure and size a timing pulley correctly, share tips on maintenance for longevity, and explain the crucial differences between timing pulleys and traditional systems like V-belt pulleys. Along the way, you’ll discover practical examples of timing pulley applications in modern machinery and learn how to troubleshoot common issues to keep your system running smoothly.

By the end of this guide, you’ll have all the knowledge you need to choose a timing pulley that enhances precision, boosts efficiency, and stands the test of time. Let’s get started!

What Is a Timing Pulley and How Does It Work?

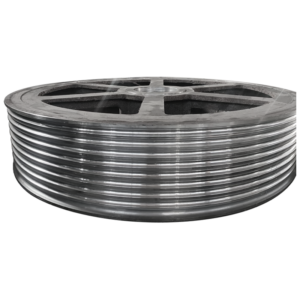

A timing pulley is a specialized mechanical component used in systems that require precise motion and synchronization. Unlike standard pulleys, timing pulleys feature teeth along their surface that interlock with the teeth of a timing belt. This ensures a positive engagement between the two, preventing slippage and enabling accurate transmission of power.

Timing pulleys are essential in applications where precision and efficiency are critical, such as in manufacturing equipment, automotive engines, and robotics.

Different Types of Timing Pulleys and Their Applications

Timing pulleys come in various designs to suit different needs:

• HTD (High Torque Drive) Pulleys: Ideal for high-torque applications due to their rounded tooth profiles.

• T-Series Pulleys: Commonly used in synchronous drives, offering balanced performance.

• Double-Sided Timing Pulleys: Designed for systems that require power transmission on both sides of the belt.

Understanding the application and load requirements will help you narrow down the options.

Materials Used in Timing Pulleys: Which One Should You Choose?

The material of a timing pulley affects its durability, weight, and resistance to wear:

• Aluminum: Lightweight and corrosion-resistant, ideal for general applications.

• Steel: Stronger and more durable, suitable for heavy-duty uses.

• Plastic: Lightweight and cost-effective, perfect for light-load systems.

Choosing the right material depends on your system’s environment and load demands.

Key Factors to Consider When Selecting a Timing Pulley

When choosing a timing pulley, consider these essential factors:

• Pitch: The distance between the centers of two adjacent teeth, which must match the belt.

• Number of Teeth: Determines the pulley’s diameter and speed ratio.

• Width: Should accommodate the belt size for optimal engagement.

• Tooth Profile: Match the tooth shape to your timing belt for proper fit.

These details ensure compatibility and efficiency in your system.

How to Measure and Size a Timing Pulley Correctly

Sizing a timing pulley involves precise measurements:

• Measure the pitch diameter to determine the pulley size.

• Count the number of teeth to confirm compatibility with the timing belt.

• Verify the belt width to ensure proper fit and engagement.

Using accurate measurements avoids misalignment and improves overall performance.

Timing Pulley Maintenance: Tips for Longevity and Performance

Proper maintenance ensures your timing pulley performs at its best:

• Regularly inspect the pulley and belt for wear or damage.

• Keep the pulley clean to prevent debris from interfering with operation.

• Check for proper tension in the belt to avoid slippage or overloading.

Routine maintenance reduces downtime and extends the life of your components.

Timing Pulley vs. V-Belt Pulley: Understanding the Differences

Timing pulleys differ significantly from V-belt pulleys in their design and function:

• Timing Pulley: Provides precise synchronization, no slippage, and higher efficiency.

• V-Belt Pulley: Relies on friction, making it better for applications with moderate precision needs.

Choosing between the two depends on your system’s requirements.

Applications of Timing Pulleys in Modern Machinery

Timing pulleys are widely used across industries:

• Manufacturing Equipment: Ensuring synchronized movement in conveyors and robotic arms.

• Automotive Engines: Regulating timing for valves and camshafts.

• Medical Devices: Supporting precision movements in diagnostic machines.

Their versatility makes them indispensable in various fields.

Common Issues with Timing Pulleys and How to Solve Them

Even the best timing pulley systems can encounter issues:

• Misalignment: Causes uneven wear; fix by realigning the components.

• Belt Slippage: Results from improper tension; adjust the belt to resolve.

• Excessive Noise: Indicates wear or debris; clean and inspect the pulley system.

Addressing these issues promptly keeps your system running smoothly.

Conclusion

Choosing the right timing pulley is critical for ensuring precision, efficiency, and durability in your system. By understanding the types, materials, sizing, and maintenance requirements, you can make an informed decision that aligns with your specific needs. Whether you’re working with high-torque machinery or precision devices, the right timing pulley will enhance performance and reduce downtime.