I. Working Principles and Structural Characteristics

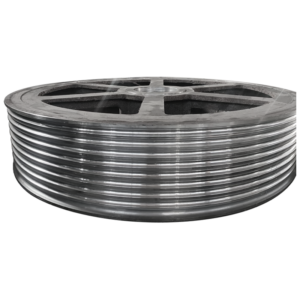

Belt Drive Systems transmit power through friction between flexible belts and pulleys, classified as friction drives. Key features include:

- Smooth operation with low noise, offering cushioning and vibration damping

- Simple structure, lower cost, easy installation and maintenance

- Belt slippage during overload protects equipment, but transmission ratio is less precise

- Suitable for applications with large center distances, but requires tensioning devices

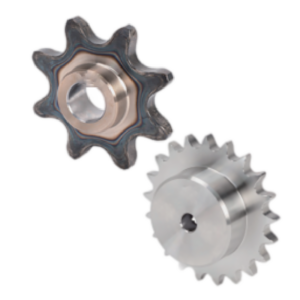

Chain Drive Systems transmit power through meshing of chains and sprocket teeth, classified as positive engagement drives. Key features include:

- Accurate transmission ratio, high efficiency, no initial tension required

- High load capacity, suitable for heavy-duty and low-speed applications

- Strong environmental adaptability, operable in harsh conditions (high temperature, dusty environments)

- Requires lubrication, relatively higher noise levels, and chain link wear issues

II. Performance Comparison

| Comparison Dimension | Belt Drive Systems | Chain Drive Systems |

|---|---|---|

| Transmission Accuracy | Lower, with slip rate | Higher, good synchronization |

| Transmission Efficiency | 85%-95% | 95%-98% |

| Speed Range | Typically ≤30 m/s | Typically ≤15 m/s |

| Load Capacity | Smaller | Larger |

| Maintenance Requirements | Regular tension adjustment, belt replacement | Regular lubrication, wear inspection |

| Service Life | Affected by aging, typically 1-3 years | Longer, but wear must be monitored |

| Noise Level | Low | Higher |

| Cushioning Performance | Excellent | Poor |

III. Application Scenarios

Preferred scenarios for belt drives:

- Equipment sensitive to noise and vibration (office equipment, precision instruments)

- Transmission systems requiring overload protection

- Applications with large center distances needing flexible connections

- Light-duty transmission applications where low cost is prioritized

Preferred scenarios for chain drives:

- Systems requiring synchronous transmission (engine timing systems)

- Heavy-duty, low-speed industrial equipment (conveyors, cranes)

- Transmission in harsh environments (agricultural machinery, mining equipment)

- Applications requiring precise transmission ratios with limited space

IV. Selection Recommendations

- Based on load characteristics: Belt drives for light loads and high speeds; chain drives for heavy loads and low speeds

- Based on environmental conditions: Chain drives more reliable in dusty, humid environments; both suitable in clean environments

- Based on precision requirements: Chain drives for high-precision synchronization; belt drives where slight slippage is acceptable

- Based on maintenance conditions: Belt drives simpler for hard-to-maintain locations; chain drives suitable where regular lubrication is possible

With advancements in materials science, both transmission methods continue to evolve. Synchronous belts combine the quiet operation of belts with the precision of chain drives, while new chain materials have improved noise and wear issues. Engineers should make optimal selections based on comprehensive requirements of specific application scenarios.