Introduction

V-belt pulleys and wedge belt pulleys are both widely used in power transmission systems, but they differ in design, performance, and application. Understanding these differences helps in selecting the appropriate pulley type for specific industrial needs.

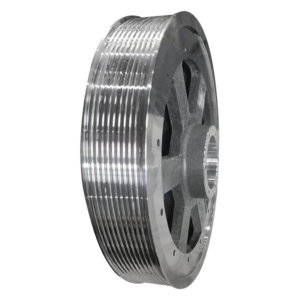

V-Belt Pulleys

Design Characteristics

- Trapezoidal Cross-Section: V-belts have a trapezoidal shape that fits into corresponding V-grooved pulleys.

- Multiple Belt Options: Available in classical (A, B, C, D) and narrow (SPZ, SPA, SPB, SPC) profiles.

Applications

- General-Purpose Power Transmission: Used in industrial machinery, agricultural equipment, and HVAC systems.

- Moderate Power Requirements: Suitable for applications with moderate torque and speed.

- Cost-Effective Solution: Preferred in applications where high precision is not critical.

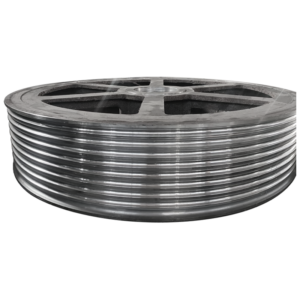

Wedge Belt Pulleys (Narrow V-Belt Pulleys)

Design Characteristics

- Narrower and Deeper Grooves: Wedge belts have a higher depth-to-width ratio, allowing better grip.

- Higher Power Density: Can transmit more power in the same space compared to classical V-belts.

Applications

- High-Speed and High-Power Transmission: Common in automotive engines, compressors, and heavy-duty machinery.

- Compact Drive Systems: Ideal where space constraints exist but high power transfer is needed.

- Improved Efficiency: Reduced slippage makes them suitable for precision applications.

Key Differences in Application

| Feature | V-Belt Pulleys | Wedge Belt Pulleys |

|---|---|---|

| Power Capacity | Moderate | Higher |

| Speed Range | Medium to high | Very high |

| Space Efficiency | Requires more space | Compact design |

| Cost | Lower | Higher (but more efficient) |

| Common Uses | Fans, conveyors, pumps | Automotive, high-torque drives |

Conclusion

While both V-belt and wedge belt pulleys serve power transmission needs, wedge belts are better suited for high-power, high-speed, and space-constrained applications, whereas classical V-belts remain a cost-effective choice for general industrial use.