In mechanical transmission systems, belt pulleys are commonly used components, and taper bushes are widely applied to connect pulleys to shafts. Featuring a simple structure, easy installation, and reliable locking performance, taper bushes are extensively used in motors, fans, gearboxes, and other equipment. This article introduces the principles of matching taper bushes with pulleys and discusses key parameters such as bore size, torque, and speed.

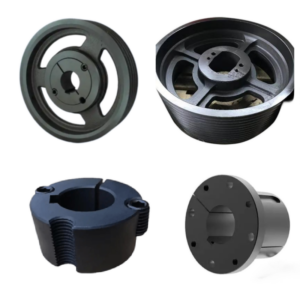

1. Basic Structure of Taper Bush and Pulley

A taper bush is a sleeve with a tapered outer surface and a keyed inner bore, used to secure a pulley to a shaft. During installation, the tapered bore of the pulley fits with the taper bush. Tightening the screws generates radial locking force, ensuring a secure and gap-free connection between the shaft and the pulley.

Pulleys are usually designed with standard taper bores and are compatible with various taper bush sizes, allowing flexibility in shaft diameter matching.

2. Bore Size Matching

The selected taper bush must match the actual shaft diameter. Standard taper bush bore sizes typically range from 14 mm to 100 mm or more, with common models such as: 1008, 1210, 1610, 2012, 2517, 3020, 3535, 4030, etc.

Examples:

- For a motor shaft diameter of 25 mm, a 1210–25 taper bush is suitable.

- For a 45 mm shaft, a 2012–45 taper bush can be used.

Notes:

- The taper bush bore must exactly match the shaft diameter.

- The bore includes a keyway; the shaft should also have a key to ensure proper torque transmission.

- The taper bush must match the pulley’s taper bore series — do not mix incompatible series.

3. Torque and Speed Considerations

When selecting the combination of taper bush and pulley, torque and rotational speed (RPM) must be considered. Excessive torque can cause slippage or damage to the bush, and high RPM may introduce centrifugal forces affecting pulley performance.

The torque-handling capacity of a taper bush depends on its model and the number and size of its locking screws. Below is a simplified reference (actual data should be verified with the manufacturer’s specifications):

| Taper Bush Model | Max Shaft Diameter (mm) | Max Torque (Nm) | Max Speed (rpm) |

|---|---|---|---|

| 1008 | 25 | 75 | 8000 |

| 1610 | 42 | 220 | 7000 |

| 2517 | 65 | 650 | 6000 |

| 3535 | 100 | 1500+ | 4000 |

⚠ Notes:

- For high-speed applications, use pulleys with high-grade dynamic balancing.

- Exceeding rated torque or speed may cause slippage, overheating, or mechanical failure.

- In applications with high impact loads, apply a higher safety factor.

4. Installation and Maintenance Tips

- Clean the taper bush and pulley bore: Remove grease, dust, and metal chips.

- Align the keyway and shaft key properly: Ensure a tight and stable fit.

- Tighten screws evenly: Use a torque wrench and tighten in a crisscross pattern in multiple steps.

- Periodically check tightness: Prevent loosening due to vibration.

- Use the extraction holes for removal: Avoid hammering to prevent damage.

5. Conclusion

A properly matched taper bush and pulley not only simplifies installation but also improves transmission efficiency and system reliability. When selecting a bush, always consider shaft size, torque, speed, and working conditions. Use the technical data provided by the manufacturer for precise selection. Proper installation and maintenance are equally important for long-term performance and operational stability.

For further selection assistance, consult product catalogs from taper bush manufacturers (such as TB Woods, Martin, or Browning), or contact your supplier.