Introduction

Choosing the right industrial belt can make or break the efficiency of your business operations. Whether you’re powering heavy machinery or ensuring seamless conveyor processes, the quality and type of industrial belt you choose play a critical role. But with so many options on the market, how do you find the perfect match for your specific needs?

In this ultimate guide, I’ll walk you through everything you need to know about industrial belts, from understanding their importance and applications to mastering the art of proper sizing and maintenance. You’ll discover the different types of industrial belts available, learn why material selection matters, and find out how investing in high-quality belts can reduce downtime and boost productivity.

I’ll also share tips on preventive maintenance to extend the life of your industrial belts and highlight common challenges businesses face in their upkeep. Plus, if you’re overwhelmed by the number of manufacturers out there, I’ll help you identify the key traits of a reliable supplier to ensure you’re getting the best value for your investment.

By the end of this guide, you’ll have the confidence to choose and maintain industrial belts that align perfectly with your business needs. Let’s dive in and simplify your decision-making process!

What Is an Industrial Belt? An Overview of Its Importance in Modern Industries

An industrial belt is a key component in machinery used to transmit power or move objects within various industrial applications. From assembly lines to packaging units, these belts ensure that operations run smoothly and efficiently. Choosing the wrong belt can lead to frequent breakdowns, costly repairs, and significant downtime.

Key Factors to Consider When Selecting an Industrial Belt for Your Machinery

To select the ideal industrial belt, consider these critical factors:

• Load Capacity: Ensure the belt can handle the weight and stress of your application.

• Speed Requirements: Match the belt’s speed capacity with your machinery’s specifications.

• Operating Environment: Take into account factors like temperature, humidity, and exposure to chemicals.

• Durability and Material: Opt for belts that are designed to withstand your specific conditions.

Different Types of Industrial Belts and Their Specific Applications

Industrial belts come in various types, each suited to specific purposes. Here are the most common ones:

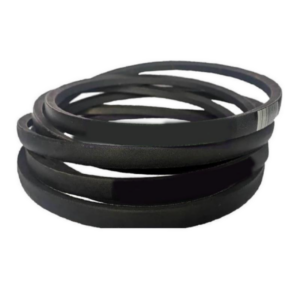

• Flat Belts: Ideal for high-speed, low-power applications.

• V-Belts: Designed for transmitting power in compact spaces.

• Timing Belts: Perfect for synchronized movement in precision applications.

• Conveyor Belts: Used for moving materials in industries like manufacturing and logistics.

• Round Belts: Commonly used in light-duty operations and packaging.

Materials Matter: Understanding the Composition of Industrial Belts

The material of an industrial belt significantly impacts its performance. Common materials include:

• Rubber: Known for its flexibility and durability.

• Polyurethane (PU): Resistant to wear and chemicals, ideal for demanding environments.

• Leather: Traditional material for flat belts in certain applications.

• Fabric: Often reinforced for added strength in conveyor belts.

Choosing the right material ensures your belt lasts longer and performs reliably.

How to Measure and Size an Industrial Belt for Optimal Performance

Accurate measurements are essential to ensure the belt fits and functions correctly. Here’s how to measure:

• Determine the Belt Length: Measure the circumference of the pulleys.

• Check the Width: Match the width to the pulleys for proper alignment.

• Assess the Thickness: Ensure the belt’s thickness meets the load requirements.

Common Challenges Faced by Businesses in Maintaining Industrial Belts

Even the best industrial belts require proper maintenance. Common challenges include:

• Wear and Tear: Caused by overloading or environmental factors.

• Misalignment: Leads to uneven wear and reduced efficiency.

• Inadequate Lubrication: Increases friction and shortens belt life.

• Improper Storage: Exposure to sunlight or moisture can degrade belt materials.

Benefits of Investing in High-Quality Industrial Belts for Longevity and Reliability

Investing in high-quality industrial belts offers numerous benefits, including:

• Reduced downtime and maintenance costs.

• Enhanced performance and efficiency.

• Longer lifespan, resulting in better ROI.

• Improved safety and reliability in operations.

Comparing Industrial Belt Manufacturers: What to Look for in a Trusted Supplier

Finding a reliable supplier ensures consistent quality and support. Here’s what to consider:

• Reputation: Look for reviews and testimonials from other businesses.

• Range of Products: A diverse selection indicates expertise and adaptability.

• Technical Support: Ensure the supplier offers guidance on selection and installation.

• Warranty and After-Sales Service: These reflect the manufacturer’s confidence in their products.

Preventive Maintenance Tips for Prolonging the Life of Your Industrial Belt

Proper maintenance can significantly extend the life of your industrial belts. Follow these tips:

• Regular Inspections: Check for signs of wear and replace belts as needed.

• Proper Tensioning: Ensure the belt tension is within the recommended range.

• Cleanliness: Keep belts free from debris and contaminants.

• Lubrication: Apply appropriate lubrication to reduce friction.

By understanding the key aspects of industrial belts, you can make informed decisions that improve efficiency, reduce downtime, and save costs for your business. The right belt, paired with proper maintenance and a trusted supplier, ensures your operations run seamlessly for years to come.