In mechanical engineering, the design and application of transmission components such as pulleys, gears, couplings, and chains are critical to the performance, reliability, and lifespan of machinery. Optimizing these components requires careful consideration of load, speed, materials, and environmental conditions.

1. Pulleys: Design and Material Considerations

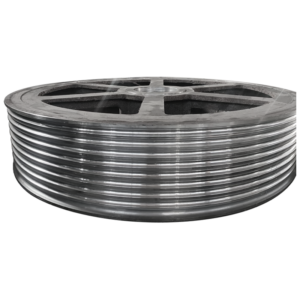

Pulleys are widely used in belt-driven systems for power transmission. Key technical requirements include:

- Dimensional Accuracy and Tolerance: Accurate pulley diameter and groove profile are essential for maintaining proper belt tension and reducing slippage. For V-belt drives, the pitch diameter DpD_pDp must satisfy:

Dp=vn⋅60D_p = \frac{v}{n} \cdot 60Dp=nv⋅60

where vvv is belt linear speed (m/s) and nnn is rotational speed (rpm). Even small deviations can lead to vibration and uneven wear.

- Material Selection: Materials must withstand tensile stress, bending, and fatigue. Common choices include:

- Cast Iron: High compressive strength, good wear resistance, economical.

- Steel Alloys: High tensile strength, suitable for high-speed or heavy-load applications.

- Aluminum or Composite Materials: Lightweight, corrosion-resistant, suitable for moderate loads.

- Surface Finish and Friction: Groove surface roughness should ensure sufficient grip without accelerating belt wear. For V-belts, a surface roughness RaRaRa of 1–2 µm is recommended.

- Load and Speed Capacity: Pulleys must handle the transmitted power PPP without exceeding material limits:

τ=P2πn/60\tau = \frac{P}{2\pi n/60}τ=2πn/60P

where τ\tauτ is torque, PPP is power, and nnn is rotational speed. Exceeding allowable torque can cause deformation or failure.

2. Gears, Couplings, and Chains

- Gears: Tooth geometry accuracy, pitch line velocity, and material hardness are critical. Contact stress σc\sigma_cσc is calculated by:

σc=Ftb⋅dm⋅K\sigma_c = \sqrt{\frac{F_t}{b \cdot d_m} \cdot K}σc=b⋅dmFt⋅K

where FtF_tFt is tangential load, bbb is face width, dmd_mdm is pitch diameter, and KKK is stress factor.

- Couplings: Must transmit torque while accommodating misalignment. Torsional stiffness and damping properties should be selected based on system resonance frequencies to prevent fatigue failure.

- Chains and Sprockets: Chain pitch, tensile strength, and lubrication are critical. The allowable tensile load TallowT_{allow}Tallow can be derived from material yield strength and safety factor:

Tallow=σy⋅ASFT_{allow} = \frac{\sigma_y \cdot A}{SF}Tallow=SFσy⋅A

where σy\sigma_yσy is yield stress, AAA is cross-sectional area, and SFSFSF is safety factor.

3. Environmental and Operational Requirements

- Temperature and Thermal Expansion: High-speed or high-load applications generate heat. Component materials must maintain mechanical properties under elevated temperatures. For pulleys, thermal expansion ΔD\Delta DΔD should be accounted for:

ΔD=α⋅D⋅ΔT\Delta D = \alpha \cdot D \cdot \Delta TΔD=α⋅D⋅ΔT

where α\alphaα is the coefficient of thermal expansion, DDD is diameter, and ΔT\Delta TΔT is temperature change.

- Lubrication and Maintenance: Proper lubrication reduces wear and fatigue. In some cases, self-lubricating or sealed components are preferred for maintenance-free operation.

- Vibration and Noise Reduction: Components should be designed to minimize vibration, using damping materials, precise alignment, and balancing for rotating parts.

4. Conclusion

For high-performance mechanical systems, the proper design and application of pulleys, gears, couplings, and chains are essential. Accurate calculations, suitable material selection, and consideration of operational conditions ensure efficient power transmission, reduce maintenance, and extend equipment lifespan. A systematic engineering approach combining theoretical analysis and practical testing is key to achieving reliable and durable mechanical transmission systems.