Belt pulleys are fundamental components in mechanical power transmission systems. They are the wheels that, in conjunction with belts, transfer motion and power between rotating shafts. From simple machinery to complex industrial setups, belt pulleys play a vital role in numerous applications. Understanding their types, materials, selection criteria, and maintenance is essential for ensuring efficient and reliable operation of any system that relies on belt drives.

Types of Belt Pulleys

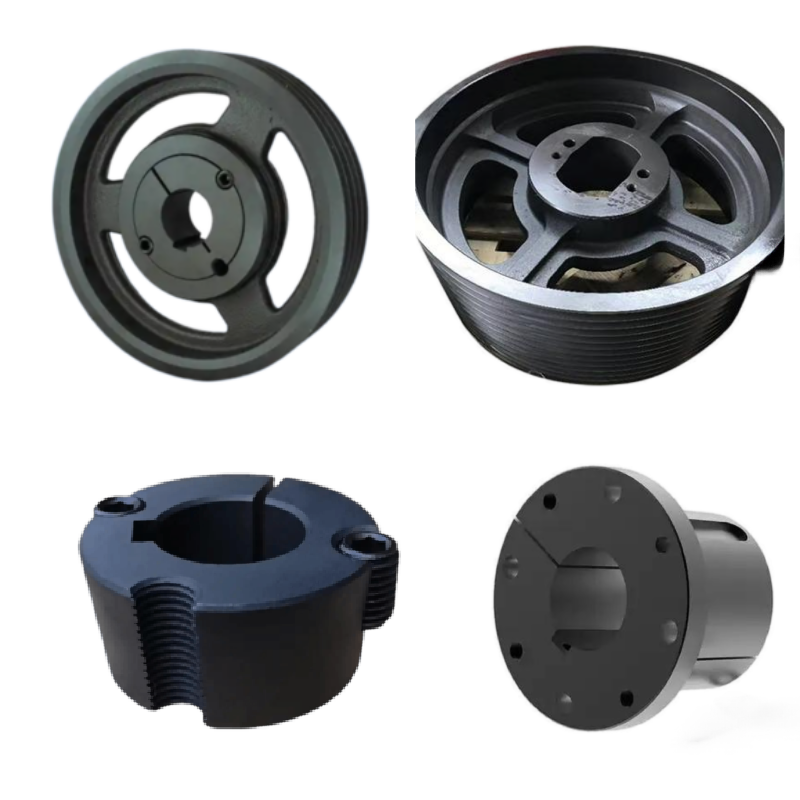

Belt pulleys come in various designs, each suited for specific needs. The most common types include:

- Flat Belt Pulleys: These are simple, flat-faced pulleys designed for use with flat belts. They are typically used for low to medium power transmission in applications with moderate speeds.

- V-Belt Pulleys: Characterized by a V-shaped groove around their circumference, these pulleys are designed to work with V-belts. The V-shape increases friction, allowing for higher torque transmission. They are widely used in various industrial and automotive applications.

- Timing Belt Pulleys (or Toothed Pulleys): These pulleys feature teeth that mesh with the corresponding teeth on a timing belt. This ensures synchronous power transmission with no slippage, making them ideal for precision applications such as robotics, printers, and CNC machines.

- Round Belt Pulleys: Pulleys designed with a groove to accept round belts, often made of polyurethane or rubber. These are commonly used for light-duty applications.

- Idler Pulleys: These are not driven but provide belt support, tensioning, and directional changes. They do not transmit power directly, but they are essential for proper system functioning.

Materials and Manufacturing

The choice of materials for a belt pulley depends on its application, operating environment, and desired performance. Common materials include:

- Cast Iron: A traditional material, offering good strength and durability, often used for heavier industrial applications. Cast iron pulleys can be cost-effective but are heavier than some other options.

- Steel: Provides high strength and durability, suitable for high-speed and high-torque applications. Steel pulleys are often used in demanding industrial environments.

- Aluminum: Lightweight and corrosion-resistant, ideal for applications where weight is a concern. Aluminum pulleys are often used in precision equipment.

- Plastics (such as Nylon and Polycarbonate): Used for lightweight, low-power applications where noise reduction and chemical resistance are desired. Plastic pulleys are cost-effective and easy to manufacture.

Manufacturing processes include casting, machining, and powder metallurgy. Precise machining is crucial for achieving the correct dimensions, surface finish, and balance of the belt pulley to ensure smooth and efficient operation.

Selection Criteria

Choosing the right belt pulley involves several considerations:

- Belt Type: The pulley must be compatible with the belt being used (flat belt, V-belt, timing belt, etc.).

- Power Requirements: The pulley must be able to handle the transmitted power without failing or causing excessive wear.

- Speed Ratio: The size of the driven and driving pulleys determines the speed ratio between the shafts.

- Environmental Conditions: Considerations should be given to operating temperature, humidity, and chemical exposure.

- Shaft Diameter and Mounting: The bore diameter of the pulley must match the shaft, and the mounting method (keyway, set screws, etc.) must be appropriate.

- Pulley Diameter and Face Width: These depend on the required belt speed and contact area between the belt and pulley.

- Number of Grooves (for V-belt pulleys): Should match the number of V-belts in the system.

Maintenance and Troubleshooting

Proper maintenance is vital for ensuring the longevity and reliable operation of belt pulley systems. Regular inspection should include:

- Checking for Wear and Damage: Look for cracks, chips, or excessive wear on the pulley surfaces.

- Ensuring Proper Alignment: Misaligned pulleys can cause belt wear and premature failure.

- Maintaining Correct Belt Tension: Too much or too little tension can lead to problems.

- Keeping Pulleys Clean: Remove any debris or dirt that can affect belt performance.

- Lubricating moving parts (if applicable): Some idler pulleys may require lubrication.

Troubleshooting common issues may involve:

- Belt Slippage: Often caused by insufficient tension or worn pulleys.

- Belt Wear: May be due to misalignment, incorrect belt type, or damaged pulleys.

- Excessive Noise: Can be due to misalignment, damaged bearings, or loose components.

Conclusion

Belt pulleys are critical for efficient mechanical power transmission, and understanding the nuances of their design, materials, selection, and maintenance is paramount. By selecting the right type of belt pulley and implementing a proper maintenance program, engineers and operators can ensure the reliable and long-lasting performance of their machinery. Whether for simple home appliances or complex industrial machinery, the humble belt pulley is a vital component in the modern world of mechanical engineering.