Sprockets are key mechanical components used in power transmission systems with roller chains. When working internationally, understanding the differences between American (ANSI) and European (DIN/ISO) sprocket standards is essential, especially when reading model numbers or specifying hub types.

📘 1. ANSI (American Standard) Sprocket Naming – Common in North America and Japan

📌 Model Format:

复制编辑XXB-YY

Example: 60B-15

60= Chain number (based on pitch size in inches; here, 0.75 inches)B= Hub type (A = no hub, B = single hub, C = double hub)15= Number of teeth

🔢 Common ANSI Chain Numbers and Pitch (in inches):

| Chain No. | Pitch (P) | Roller Dia. |

|---|---|---|

| 25 | 0.25 | 0.130 |

| 35 | 0.375 | 0.200 |

| 40 | 0.5 | 0.312 |

| 50 | 0.625 | 0.400 |

| 60 | 0.75 | 0.469 |

| 80 | 1.00 | 0.625 |

The pitch usually follows a multiple of 1/8 inch (e.g. 60 × 1/8 = 0.75”).

📗 2. DIN/ISO (European Standard) Sprocket Naming – Common in Europe, Asia, Middle East

📌 Model Format:

复制编辑XXB-Y-ZT

Example: 08B-1-17T

08B= Chain number (based on pitch in millimeters; 08B = 12.7 mm)1= Number of chain rows (1 = single, 2 = double, 3 = triple)17T= Number of teeth (T = teeth)

🔢 Common European Chain Numbers and Pitch (mm):

| Chain No. | Pitch (P) | Roller Dia. (d1) | Roller Width (b1) |

|---|---|---|---|

| 06B | 9.525 | 6.35 | 5.72 |

| 08B | 12.7 | 8.51 | 7.75 |

| 10B | 15.875 | 10.16 | 9.65 |

| 12B | 19.05 | 12.07 | 11.68 |

| 16B | 25.4 | 15.88 | 17.02 |

DIN chains follow the metric system and conform to DIN 8187 or ISO 606 standards.

🔍 3. Key Differences Between ANSI and DIN/ISO Sprockets

| Feature | ANSI (American) | DIN/ISO (European) |

|---|---|---|

| Unit System | Imperial (inches) | Metric (mm) |

| Model Format | e.g. 60B-15 | e.g. 08B-1-17T |

| Tooth Profile | Thicker, robust | Slimmer, more precise |

| Pitch System | 1/8 inch multiples | 6.35 mm multiples |

| Usage Regions | USA, Canada, Japan | Europe, China, SE Asia |

| Interchangeability | ❌ Not compatible | ❌ Not compatible |

🧩 4. How to Identify Hub Types in European (DIN) Sprockets

Unlike ANSI, DIN/ISO sprockets do not explicitly state the hub type in the model number. However, you can identify it using the following methods:

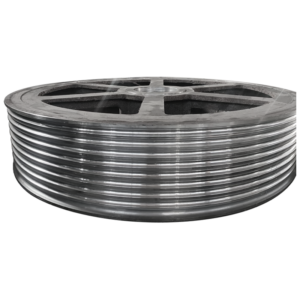

🔧 A. Based on Physical Structure (Three Main Types):

| Type | Description | Hub Style |

|---|---|---|

| Type A | Flat sprocket | No hub |

| Type B | One-sided hub | Hub on one side only |

| Type C | Double hub sprocket | Hubs on both sides |

You can see the hub structure clearly in side-view drawings or physical samples.

📝 B. Based on Product Descriptions or Supplier Details

Watch for keywords in the product name or catalog:

| Description | Meaning |

|---|---|

| “With hub” | Has a hub (Type B or C) |

| “Hubless” / “Flat” | No hub (Type A) |

| “Solid hub sprocket” | Integrated hub structure |

| “Single-side hub” | Type B |

| “Double-side hub” | Type C |

Example:

08B-1-17T flat plate sprocket→ Type A08B-1-17T with hub→ Type B or C

🆔 C. Manufacturer-Specific Codes

Some suppliers may add custom suffixes:

08B-1-17T-A→ Type A08B-1-17T-B→ Type B08B-1-17T-C→ Type C

⚠️ Note: This is not standardized, so always refer to the catalog or drawing.

✅ 5. Practical Tips for Sales and Technical Staff

- Always confirm hub type when quoting or ordering.

- Include notes like: “with single hub” or “hubless flat type” in your quotes.

- Provide drawings to avoid misunderstanding.

- ANSI and DIN sprockets cannot be interchanged — match the customer’s chain standard.

🧾 Summary

Understanding sprocket model numbers and hub types is essential for correct selection and international communication. Whether you’re dealing with ANSI or DIN standards, pay close attention to pitch, hub design, and regional usage preferences.